R&D capabilities

As a professional supplier of fan blades and fans in the air-conditioning industry, Langdi Group has cultivated a professional R&D team with more than 30 years of accumulation in the fan industry. Over the years, it has cooperated with research institutes such as Xijiao University, Huazhong University and Sichuan University. Adhere to the talent strategy, adhere to independent innovation, through the introduction and training of R & D design, process manufacturing, test and inspection, finishing, mechanical and electrical integration, fluid machinery and other technical forces, constantly digest and absorb the technical commanding heights of the EC motor industry, combined with customer needs And the development of technology, the implementation of quality strategy. Through continuous iterative innovation, we will establish the core business, emerging business and seed business needed for the company's sustainable development, and provide a continuous source of power for the realization of the company's vision.

Advanced electronic control technologyElectronic control is the control brain in the entire fan system. For this, we have a professional electronic R&D engineer that uses a vector-positive wave scheme without position sensing to perfectly match the motor drive and aerodynamic output.

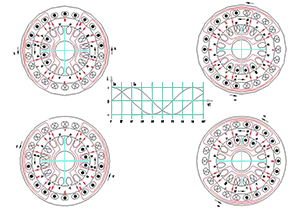

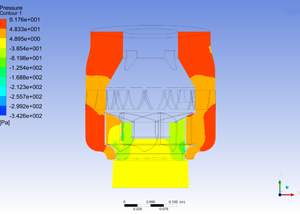

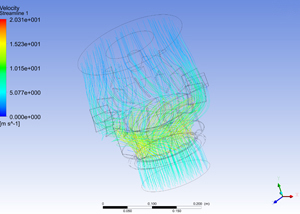

Mature aerodynamicsThe products developed by the Langdi Group with more than 20 years of technology and fans have been sold to major well-known companies around the world and involved various types of ventilation and electrical appliances. With advanced simulation technology and years of experience in aerodynamics, R&D personnel can quickly achieve high-efficiency, low-noise aerodynamic product designs.

Manufacturing Capability

Providing customers with products that are both competitive and highly reliable has always been the goal of us. Stable quality and timely delivery are not only the needs of customers, but also the root cause of corporate profits. Therefore, improving the reliability of equipment, automating the degree, continuously optimizing the process, optimizing the supply chain, and training front-line employees, lean manufacturing has always been the core factor and the basic condition for the sales market of Randy products.

Customization and Service

As an important and even core component of the whole unit, the fan should serve for performance of the whole unit. Therefore, in the initial stage of project development, our team members will actively participateand propose solutions in a targeted manner in the framework of obeying the customer's overall structure and performance requirements. This is a weapon for us to maintain a good mutual benefit relationship with our customers. Especially for project-oriented products, with their individualized aspect, we can try our best to help customers to invest less, and meet customer needs faster, better and more economically.

Detection Capability

We have complete quality testing equipment and quality management mechanism. We strictly control unqualified raw materials from the raw materials entering the factory and the assembly line and product assembly process, and do not transfer to the production line. The unqualified parts are not transferred to the next process, and the unqualified products are not discharged. And collect and accumulate data that reflects the quality of the situation, providing information for measuring and analyzing process capabilities, monitoring processes, and improving quality.